CII Roll App

A data bases for mapping of the entire conveyor system for condition monitoring of components including rolls. Images and notes are then recorded of failures to components, change-outs etc, generating emails to prioritise maintenance.

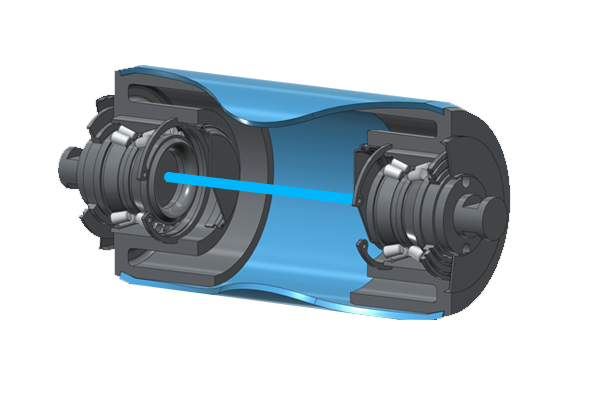

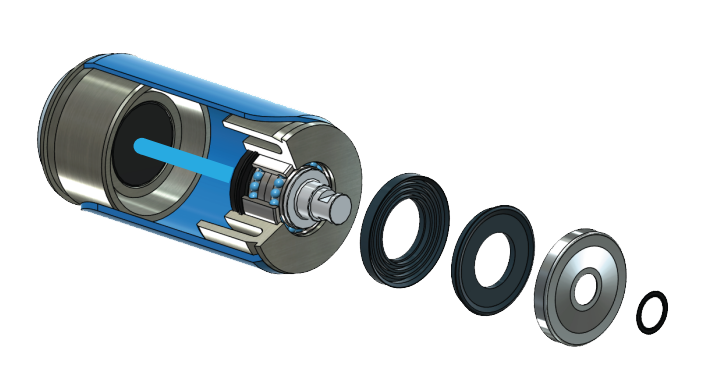

CII Concealed Unit

CII created an industry first sealed bearing unit with negligible drag at the rim to overcome traditional causes for failure in generic rollers. The endcap is CNC machined, seating the bearings perfectly within the end cap.

Gen 7

The Gen 7 was specifically designed to improve incidents associated with failure, often inherent with conventional rollers. Thanks to Gen 7, mines & ports are using less rollers over time, resulting in increased production, and driving significant cost savings.

CII Product Development

CII is a private company who have the support of Universal Bearings, a business with locations in Melbourne, Sydney, and Brisbane. Their annual revenue exceeds $10 million. Universal Bearings is a significant shareholder in our business and has provided us with significant capacity.

CII . Roll App + Roll Technology | GEN 7 | Sealed Unit | CII Roller Technology | Long-life Roller Development

CII iFrame

DunnEasy Idler for Conveyor Idler roll change-outs – done without even lifting a conveyor belt! The iFrame Assembly replaces a fixed idler set conveyor structure. Effectively heightens safety and productivity. Conveyor Idler roller change-outs are not only safer and faster – they can be done in less than 5 minutes using standard tools. Proven in Coal, Metaliferous

Mining and Ports.

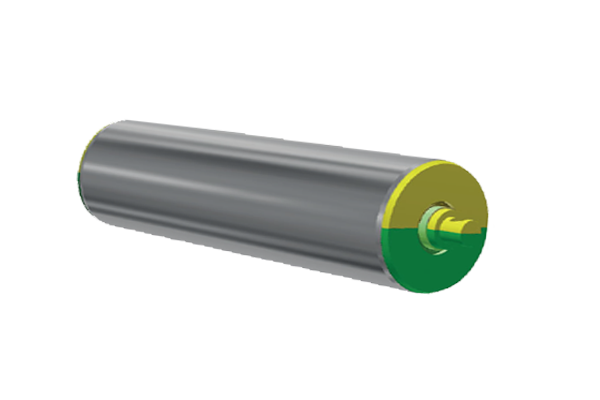

CII iRoller

CII ROLLERS superior performance delivers greater productivity. Rollers are available in Carbon Steel, VitreSteel, and Aluminium with >250,000 hours bearing life, 39.7 kN [DYN], 36.5 kN [STAT] sealed bearings.

Up to 50% lighter than conventional rollers. VitreSteel tube is ideally suited to corrosive mines and ports. This means significant increases in lifespan and less downtime.

QUALITY ASSURED

Sealed, internalised components and dynamic load eliminate the need to weld, no loss of lubrication and almost totally eliminates the ingress of debris. CII Rollers have no bearing deflection limiting failures and a low carbon footprint. CII technology out-performs within its’ field and is prone to less failures.

Our Rollers and Technology Solutions are ‘Game Changing, Disruptive Technology’ that overcomes traditional performance issues relating to bearing failure, roll balance, shell materials and is the most sophisticated technology for reliable performance on the market.

CII . TECHNOLOGY

CII Rollers and Technology Solutions are ‘Game Changing, Disruptive Technology’ that overcomes traditional performance issues relating to bearing failure, roll balance, shell materials and is the most sophisticated technology for reliable performance on the market.

CII . CERTIFIED

VitreSteel tube is designed for highly corrosive environments, is extremely hard-wearing with excellent belt-tracking characteristics. VitreSteel is rated at 780mpa plus. We confidently deliver our products with certified Quality Assurance.

CII . QUALITY

Sealed, internalised components and dynamic load eliminate the need to weld, no loss of lubrication and almost totally eliminates the ingress of debris. CII Rollers have no bearing deflection limiting failures and a low carbon footprint.