CII INNOVATION

INCREASED PRODUCTIVITY

CII TECHNOLOGY

REDUCED MAINTENANCE COSTS

CII ENGINEERING

PREDICTIVE MAINTENANCE APP

CII INNOVATION

INCREASED PRODUCTIVITY

CII TECHNOLOGY

REDUCED MAINTENANCE COSTS

CII ENGINEERING

PREDICTIVE MAINTENANCE

CII . TEL

07-4982-4814

CII . TEL

07-4982-4814

CII . FAX

07 . 5575 2017

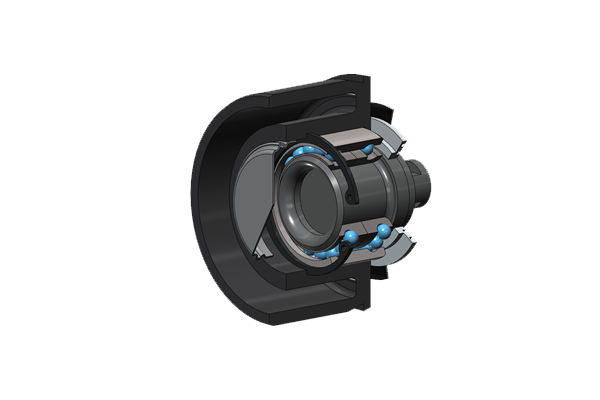

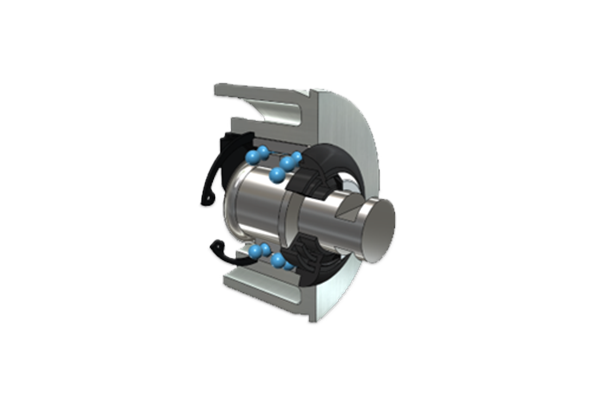

CII . SEALED UNIT

Industry first sealed bearing with no drag rim – overcomes failure in generic rollers.

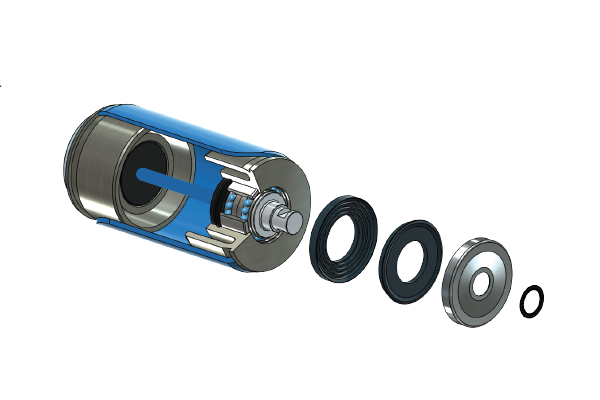

CNC Machined Endcap | Internally sealed | Prolonged Bearing Life | CII Technology

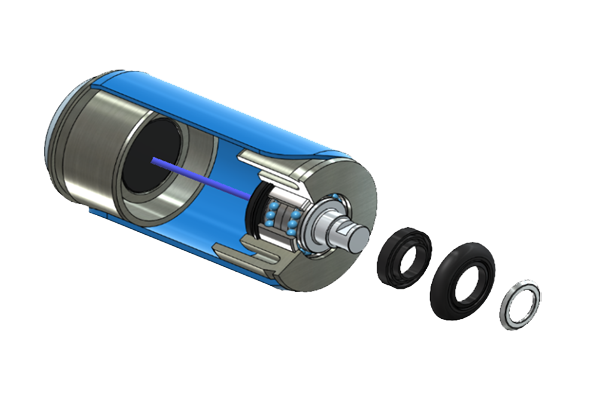

CII-GEN 7

Improves incidents associated with failure – Extended life for mines and ports | Increases Production | Cost savings | Mass swagged | No- weld roller ends. Double angle contact bearings | Double roller tapered.

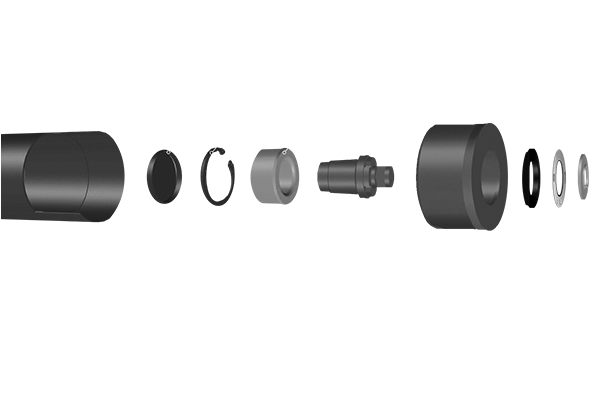

HIGH TENSILE ENDCAPS

Ideal for high speed conveyors, these engineered assemblies contain axles and bearings – Hardened alloy reduces impact of corrosion on a steel bearing assembly – decreasing maintenance issues + safety bar.

CII . BEARINGS

A conventional roller axle dictates the size of the bearings | Stub axle for higher load | Robust operation 24 hours a day, over many years. Gen 7 comes with a DAC 396837 roller bearing to achieve Dynamic Load bearing capacity.

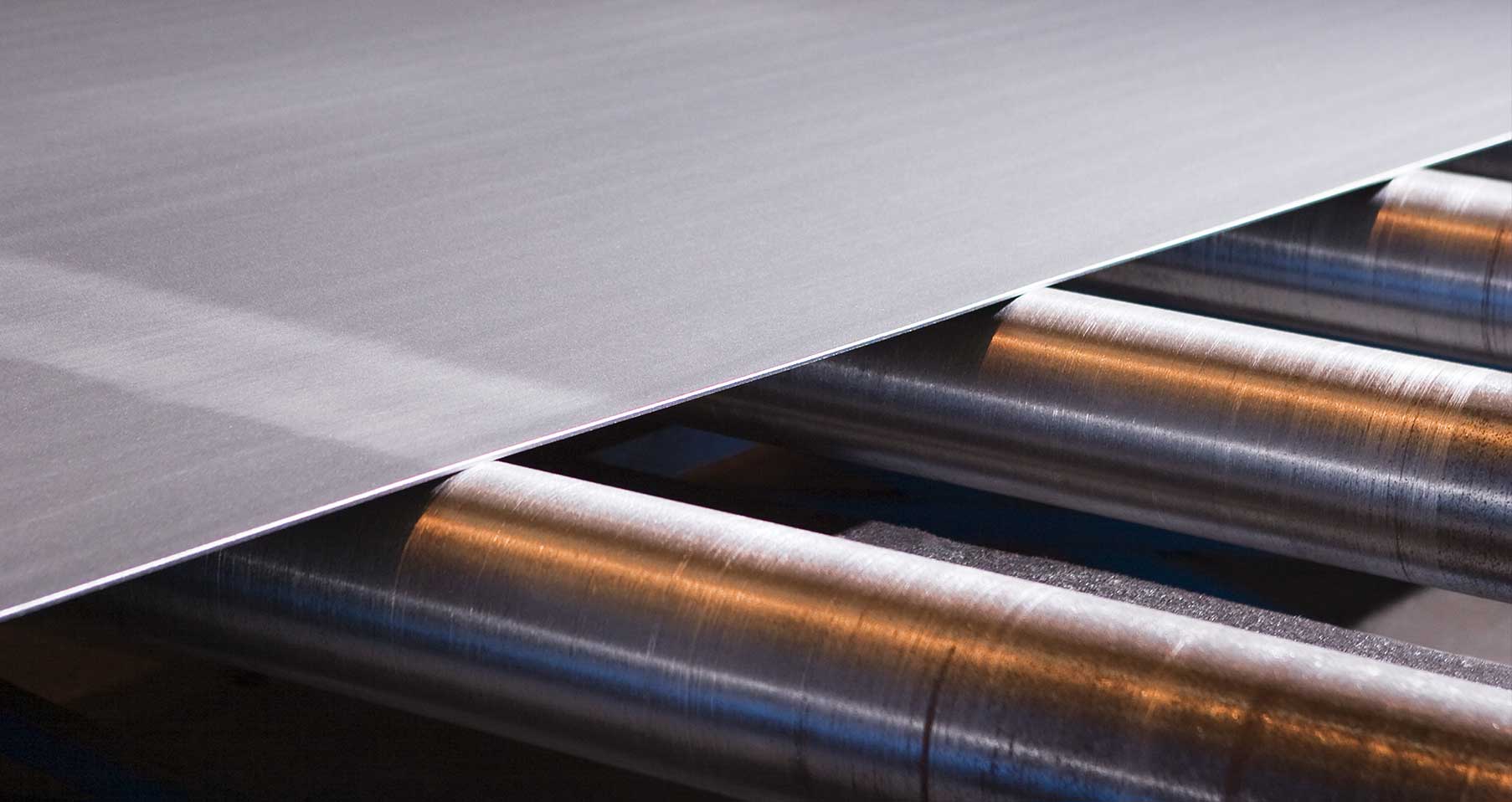

CII . ROLLER

CII stub axle boasts a larger bearing to facilitate higher load | High-performance + reliable and robust. Experience increased life span + radial and axial load. Perfectly aligned, with virtually no axle float.

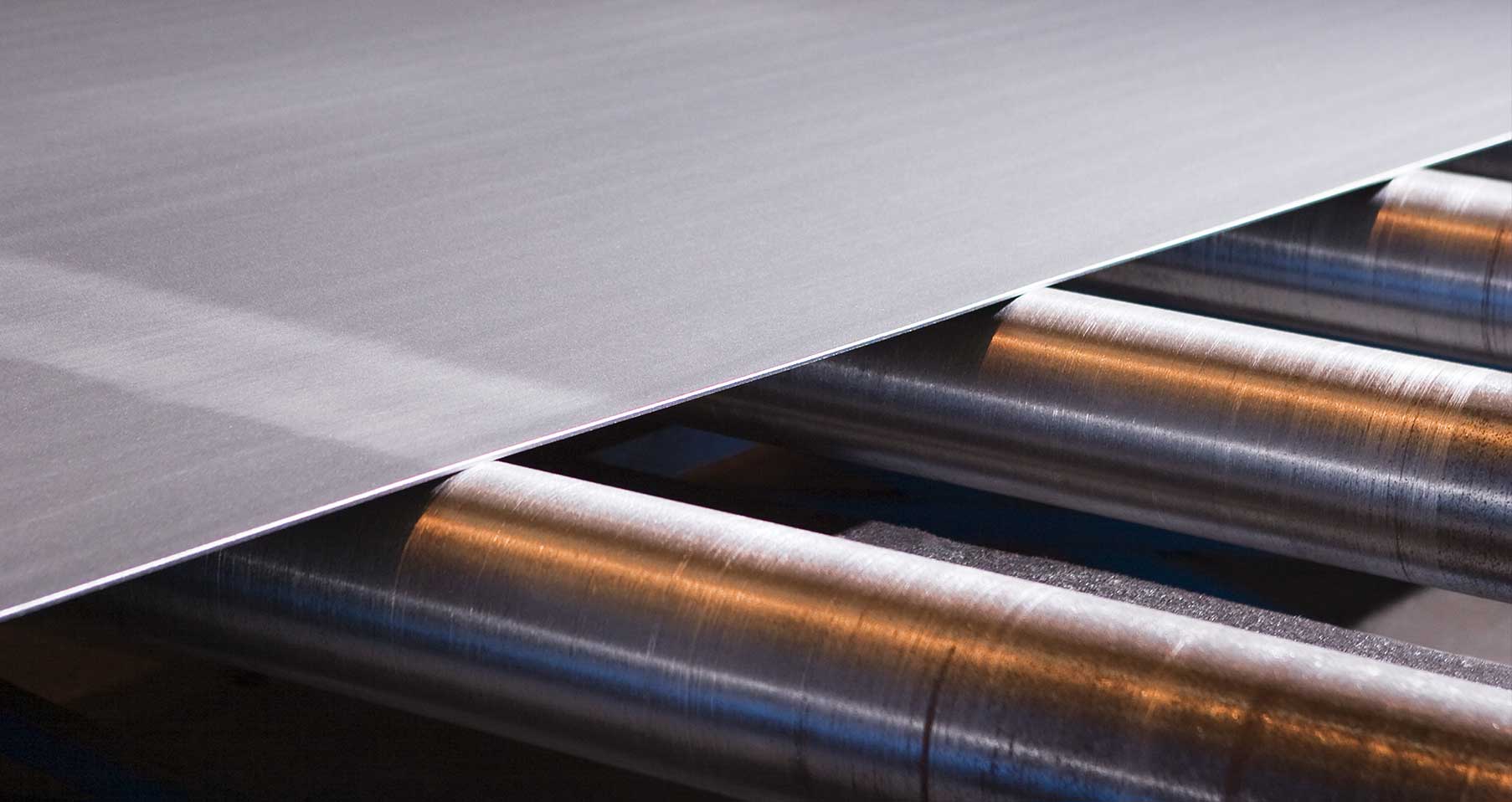

CII . VITRE STEEL

3-Tube Protocols | Carbon Steel – VitreSteel | Aluminium | Extremely tough with a 650-750 MPa. Weight: our axle significantly reduces the weight by over 1000mm in length. Serial Number | App allows to track + record.

CII assist companies by reducing unscheduled stoppages, thereby saving mines and ports costs.

Large companies benefit, with the ability to monitor off-site, saving fly-in & fly-out costs from larger mines operating from remote locations.

The iRoller means real-time monitoring for mines and ports, helping operations to predict change-outs and reducing unscheduled stoppages.me.

CII . TEL

07-4982-4814

CII . FAX

07-5575-2017