The use of the Gen 7 rolls throughout the conveyor system can lead to inventory reductions of rolls by up to 60%. The reasons are:

By reducing the range and type of rolls for various applications – using Gen 7 Rollers throughout the system reduces variability and need for greater inventory;

Reduction in manufacturing time from 12-16 weeks to about 4-6 weeks;

Improved performance of rolls reduces the greater replacement number required.

BENEFITS OF CII . iROLLER

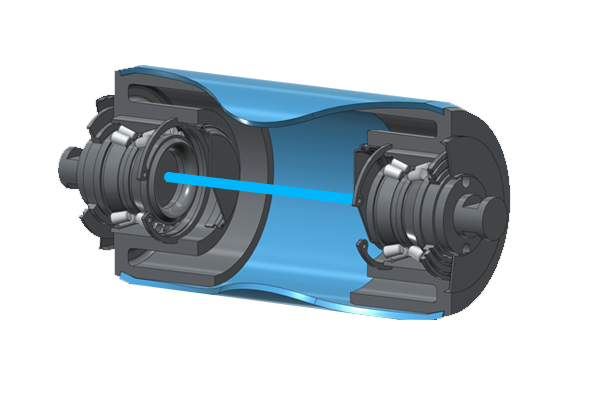

New VitreSteel Rolls

CII . TEL

07-4982-4814

CII . FAX

07-5575-2017