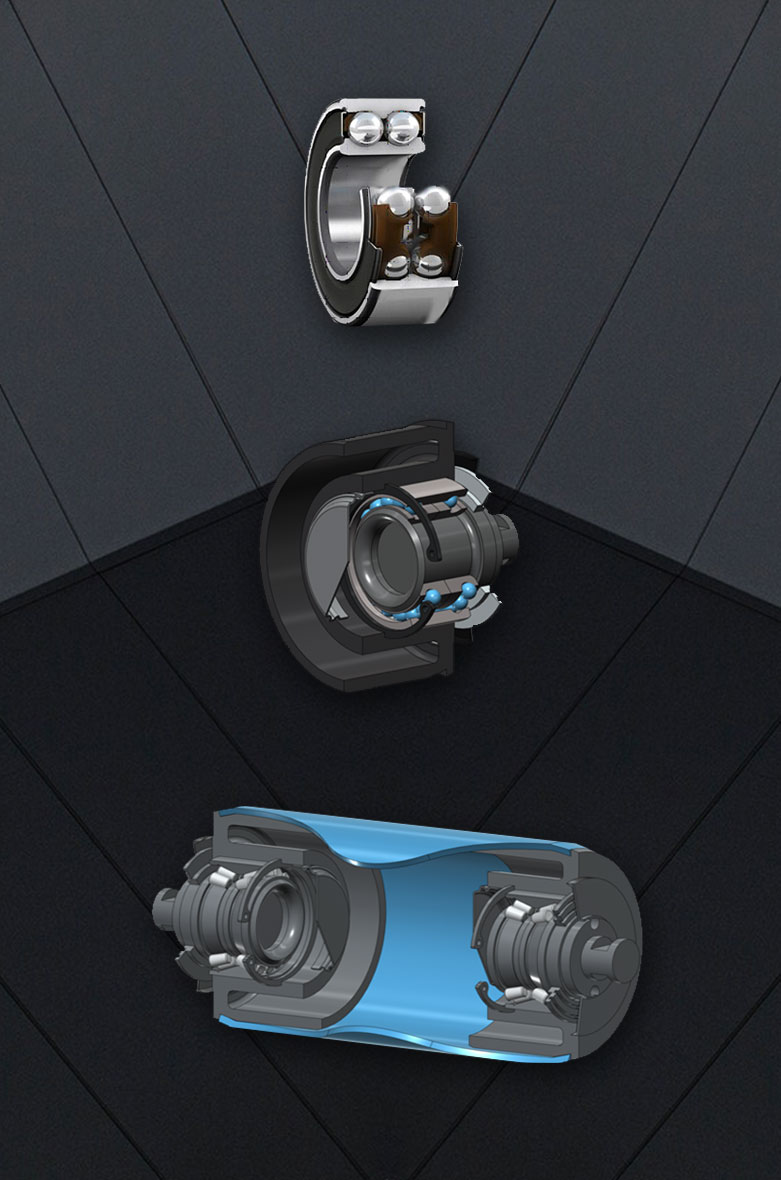

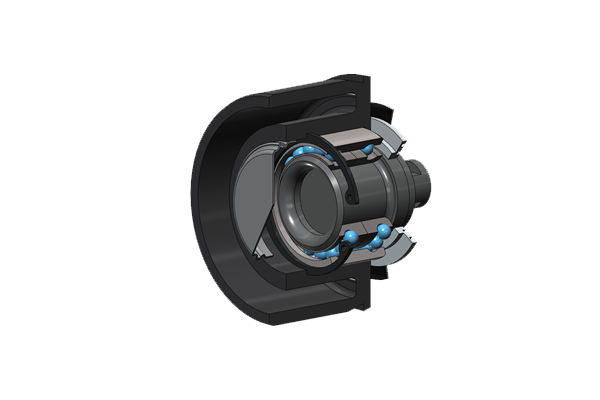

CII . SEALED UNIT

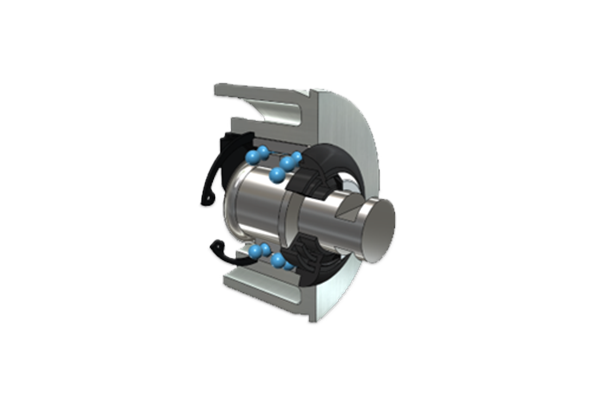

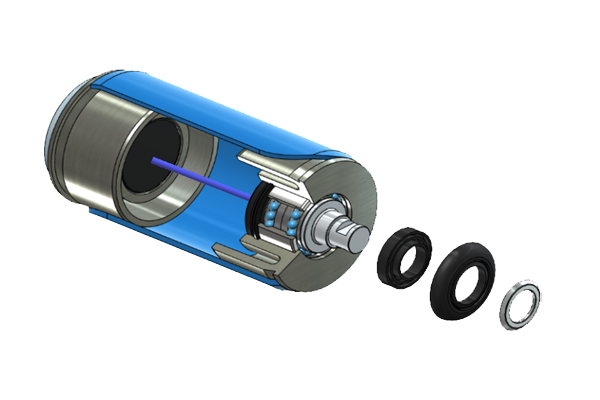

CII created an industry first sealed bearing unit with negligible drag at the rim to overcome traditional causes for failure in generic rollers. The endcap is CNC machined, seating the bearings perfectly within the end cap. The inside is further sealed to negate ingress at the back of the endcap. The internal space between the bearing and axle is secured by a special cap containing additional lubricant (grease), to prolong the life of the bearing.

CII-GEN 7

The Gen 7 was specifically designed to improve incidents associated with failure, often inherent with conventional rollers. Thanks to Gen 7, mines & ports are using less rollers over time, resulting in increased production, and driving significant cost savings. The prototype bearing assembly (endcap) is mass swagged at the end of the tube, eliminating the need to weld roller ends. Bearings can be either double angle contact, or double roller tapered.

HIGH TENSILE ENDCAPS

Ideal for high speed conveyors, these engineered assemblies contain axles and bearings. The Gen 7 is made of a hardened alloy to largely reduce the impact of corrosion on a steel bearing assembly (decreasing maintenance issues). A safety bar, similar to an axle, can be inserted between both end caps – however, there has not been a requirement for this feature, since the Gen 7 went into production.

CII . BEARINGS

A conventional roller axle dictates the size of the bearings. A stub axle uses a larger bearing to accommodate a higher load. The Gen 7 is robust and positioned to operate 24 hours a day, over many years. Gen 7 comes with a DAC 396837 roller bearing to achieve Dynamic Load : 39.7kN; and Static Load : 36.5kN. The clear advantage in using our bearing is the ability to take both radial and axial load and the bearing is perfectly aligned with virtually no axle float.

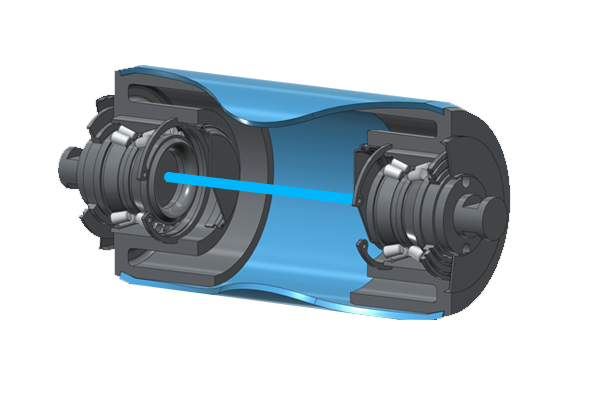

CII . ROLLER

Generally, the size of the axle in conventional rollers dictates the size of the bearings. With a stub axle you can use a larger bearing to facilitate a higher load. CII Rollers demonstrate high-performance, and are reliable and robust to operate 24 hours a day, over many years. Gen 7 has a longer life than conventional rollers and comes with a DAC 396837 roller bearing for Dynamic Load : 39.7 kN; and Static Load : 36.5kN. Handles both radial and axial load. The bearing is perfectly aligned, with virtually no axle float.

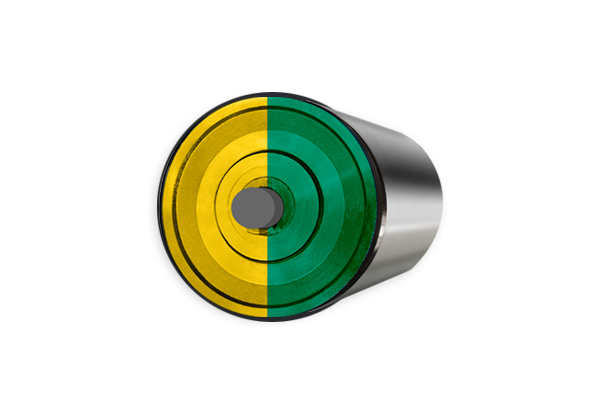

CII . VITRE STEEL

CII manufacture three tube protocols: Carbon Steel; VitreSteel; and Aluminium. Carbon Steel and Aluminium are about 280MPa. Vitre Steel is extremely tough with a 650-750 MPa. Weight: our axle significantly reduces the weight by over 1000mm in length. Each CII endcap is identified with a serial number and delivery date. One paint colour represents the year of installation, another colour indicates the length the product has been in service (eg blue – 2018, red – 2019). Your product installation can be tracked and recorded at a glance.

CII . TEL

07-4982-4814

CII . FAX

07-5575-2017